With 30 years of hands‑on experience, Podium 1 Engineering is the team you can trust for all your welding and metal repair needs — we lead the industry in precision metal joining and complex restorations. Our technicians combine deep technical knowledge with proven processes, advanced equipment, and stringent quality controls to deliver quality welding and repairs every time. We understand the critical tolerances and safety standards your projects demand and consistently exceed them. Choosing Podium 1 means partnering with a seasoned, reliable shop that values craftsmanship, accountability, and performance above all else.

WELDING

CERTIFIED WELDING INPECTION

Our team brings extensive AWS Certified Welding Inspector (CWI) expertise applied across ASME code work, Petroleum Piping, and National Board pressure vessel standards. We routinely perform code-compliant welding inspections, procedure reviews, fit-up verification, NDE coordination (including MPI, DPI, UT, and RT), and final acceptance for pressure-retaining components and piping systems. With years of hands-on service in the gas industry, we understand the critical safety and regulatory demands of gas service — from high-pressure transmission lines to process piping and pressure vessels — and deliver meticulous, documented inspections that ensure integrity, leak-free performance, and regulatory compliance. We understand the mission critical tolerances and safety standards your projects demand and consistently exceed them. Choosing Podium 1 means partnering with a seasoned, reliable shop that values craftsmanship, accountability, and performance above all else.

At Custom Podium 1 Engineering we repair virtually anything because our foundation is built on decades of real-world experience across aerospace, commercial structural steel, and industrial piping sectors. That background ensures repairs done to the standards of the most demanding industries.

What sets us apart

Aerospace‑grade precision: Aerospace work demands exacting tolerances, rigorous quality control, and repeatable processes. We apply those same standards to every repair—critical alignments, dimensional checks, and fit-ups are completed with precision measuring tools and documented to meet strict tolerances.

Structural steel expertise: Years fabricating and repairing commercial structural steel has given us deep understanding of load paths, plate and member behavior, weld sequencing, and distortion control. We design solutions that restore original strength and stiffness while minimizing residual stress and deformation.

Piping and pressure system knowledge: Repairing / Designing industrial piping taught us to manage complex joints, transitions between dissimilar materials, and stress concentrations. We apply appropriate welding procedures, preheat/post‑heat practices, and NDT to ensure integrity under cyclic and sustained loads.

Proven welding practices: Our welders are experienced in SMAW, GMAW, GTAW, FCAW and specialty processes. We develop and follow weld procedure specifications (WPS), perform procedure qualification records (PQR) when needed, and monitor interpass temperatures and heat input to preserve material properties.

Engineering‑driven repairs: Every job is backed by engineering judgment and calculations where required—stress checks, finite element analysis for complex repairs, fatigue life considerations, and bolt/weld sizing to restore or improve original performance.

Tight tolerance capability: We routinely meet tight tolerance requirements — precision jigs and fixtures, CNC fixturing, laser alignment, and coordinate measurement tools (CMM/laser trackers) ensure bores, mounts, and interfaces are returned to spec.

How we approach a repair

Inspection and assessment: Detailed visual, dimensional and, when required, non‑destructive testing (UT, RT, MT, PT) to identify root cause and extents of damage.

Engineering and planning: Develop a repair plan with calculations, material selection, welding procedures, and fixturing to control distortion and restore design intent.

Controlled execution: Certified welders and fabricators execute the repair using documented procedures, controlled preheat/post‑heat, and strict quality checkpoints.

Verification and testing: Final dimensional verification, NDT, pressure testing or functional checks as applicable to confirm the repair meets or exceeds required specifications.

Documentation: Comprehensive records including inspection reports, WPS/PQR, material traceability, and final acceptance data.

Examples of typical repairs we handle

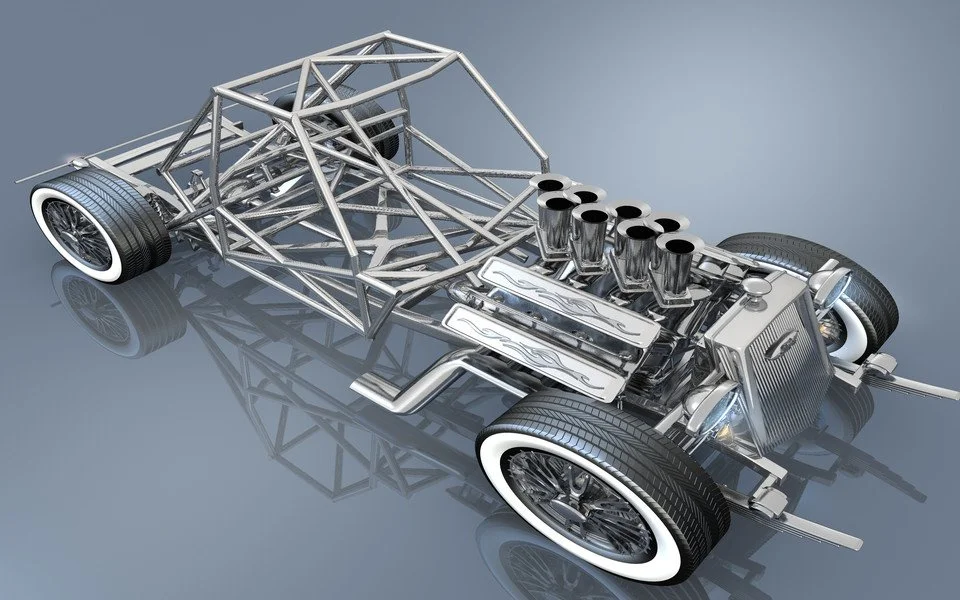

Frame straightening and reinforcement for race and offroad vehicles to restore chassis geometry within race‑legal tolerances.

Rebuilding damaged control arms, suspension mounts, and engine mounts with engineered reinforcement and precision alignment.

Repairing cracked or failed structural members in steel buildings and equipment, restoring load paths with welded splice plates or sleeves.

Restoring compromised piping systems and flanges, including dissimilar metal transitions and fatigue‑prone areas.

Replacing or reforging complex welded assemblies where heat‑treatment and precise fit are critical.

Why it matters to you Our cross‑industry experience means we don’t guess at repairs — we engineer them. That reduces downtime, prevents repeat failures, and returns components to service with confidence. Whether it’s a race chassis that must hold precise geometry lap after lap or a pressure system that must meet safety standards, our methods deliver reliability and repeatable performance.

If it’s metal and it’s broken, we have the welding skills, engineering insight, and measurement capability to make it right..

REPAIR

Podium 1 Engineering delivers CNC machining repair and manufacturing services you can trust because we engineer every component and repair precisely to industry standards. Here’s why choosing us minimizes risk, reduces downtime, and maximizes performance:

Precision that matches design intent: Our experienced engineers create CNC programs and fixturing with tight tolerances so parts meet original specifications or improved performance targets. That reduces fitment issues, vibration, premature wear, and the need for repeat work.

Standards-driven processes: We follow relevant industry standards (material specs, geometric dimensioning and tolerancing, surface finish, heat-treat and welding requirements) to ensure parts are serviceable, interchangeable, and compliant with OEM and regulatory expectations.

Root-cause repairs, not band-aids: When repairing critical components, we diagnose failure modes and design repairs that restore structural integrity and function to standard or better. That approach prevents recurring failures and extends service life.

Consistent quality control: Every part undergoes in-process inspection and final verification using calibrated metrology equipment. Documented inspection reports and traceability give you confidence that tolerances and material properties were verified.

Skilled machinists and engineers: Our team brings hands-on experience with high-precision CNC mills and lathes, multi-axis machining, and complex setups. We combine practical machining know-how with engineering judgment to deliver reliable outcomes on otherwise difficult repairs.

Fit-for-purpose material and tooling selection: We specify appropriate alloys, heat treatment, coatings, and cutting tools to achieve the right balance of strength, fatigue resistance, and machinability for each application.

Faster turnaround with fewer surprises: Accurate engineering upfront reduces rework and iterative adjustments, shortening cycle times and keeping your equipment back in service sooner.

Documented drawings and change control: We provide clear drawings, revision control, and build records so replacement parts are reproducible and future repairs are straightforward.

Choose Podium 1 Engineering when you need CNC repairs and manufactured components done right the first time — engineered precisely to industry standards for performance, safety, and longevity.